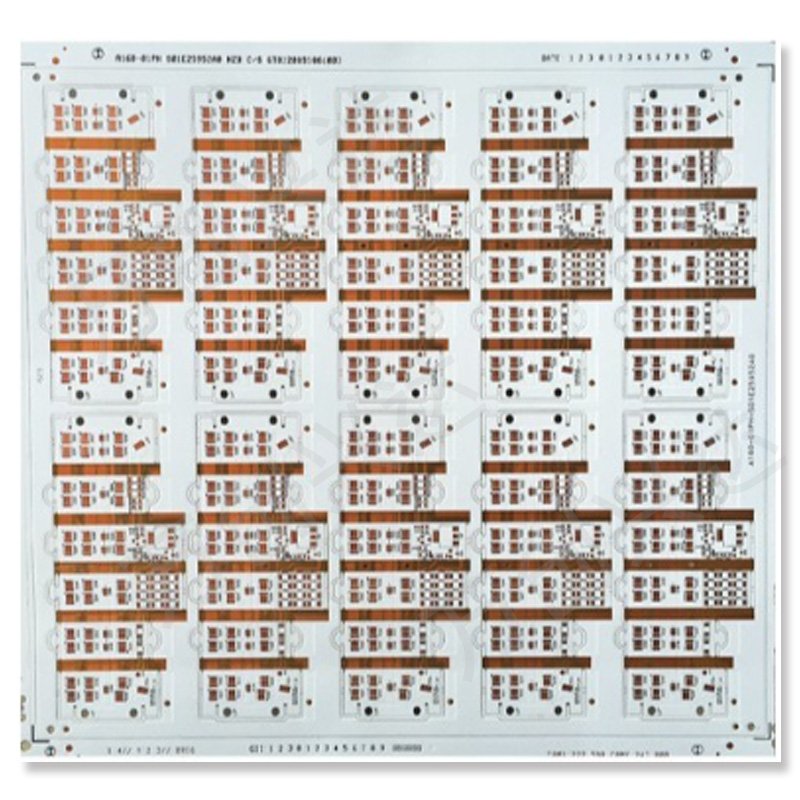

FR-4 immersed gold LED Rigid-flex pcb board

Material: Fr-4

Layer Count: 2 layers

PCB Thickness: 1.6mm

Min. Trace / Space Outer: 3/3mil

Min. Drilled Hole: 0.25mm

Via Process: Tenting Vias

Surface Finish: Lead-free spray tin

Description of rigid-flex PCB board

The birth and development of FPC and PCB gave birth to the new product of rigid-flex board. Therefore, a rigid-flex board is a flexible circuit board and a rigid circuit board that are combined together according to relevant process requirements through processes such as lamination to form a circuit board with FPC characteristics and PCB characteristics.

Initially, the basic design concept and manufacturing process of multi-layer rigid-flex boards were developed from aerospace equipment, because reliable wiring must be performed in a limited space. In some complex products, rigid-flex boards with more than 30 conductor layers are even used. On the other hand, consumer electronics products, such as mobile phones and digital cameras, have always required high-density, low-cost wiring technology, so new design concepts and manufacturing processes have emerged.

The combination of soft board and hard board can be called: rigid-flex board, soft-hard board, or rigid-flex board, when their multi-layer flexible media use flexible materials instead of glass-epoxy resin , also known as multi-layer flexible board.

Advantages and disadvantages

Advantages: The soft-hard board has both the characteristics of FPC and PCB. Therefore, it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area, which is helpful for saving the internal space of the product. , which is of great help in reducing the volume of finished products and improving product performance.

Disadvantages: The production process of soft-hard composite boards is complicated, the production is difficult, the yield rate is low, and more materials and manpower are invested. Therefore, the price is relatively expensive and the production cycle is relatively long.

The production process of rigid-soft board

1. Punching

When drilling holes in FR4 and PP films, the design of the alignment holes is different from ordinary through holes. Browning treatment is required after drilling

2. Riveting

Copper clad laminates, PP glue, and FPC circuit boards are stacked in sequence. The original old process was to laminate and press step by step, but it was a waste of time. After many attempts, it was found that it could be stacked once.

3. Lamination

This is a relatively complete step in the manufacturing of soft and hard composite panels. Most of the material is being integrated for the first time. First, the bottom layer of copper clad laminate and PP film is placed on top of the FPC board made in the previous process. A layer of PP film is placed on the FPC board, and then the last layer of copper clad laminate is placed. All materials to be laminated are placed in order and pressed together.

4 Gong board edge (also called edge trimming)

That is to say, remove the parts on the edge of the circuit board where there are no lines and no lines are planned. Afterwards, it is necessary to measure whether the material has excessive expansion and contraction, because the PI used in the production of flexible boards also expands and contracts, which has a great impact on the production of circuit boards.

5 Drilling

This step is the previous step to connect the entire circuit board, and manufacturing parameters must be made based on the design parameters.

6. Gum removal and plasma treatment.

First remove the slag produced by drilling the circuit board, and then use plasma cleaning to clean the through holes and board surface.

7. Copper deposition

This step is the process of electroplating through holes, also known as hole metallization. Achieve through-hole power conduction.

8. Flat plate plating.

The surface above the plated hole is partially plated with copper so that the copper thickness above the through hole exceeds the surface of the copper-clad board by a certain height.

9. Production of positive film of outer dry film

As in the process of making a dry film of resist for a flexible board, the circuitry to be etched on the copper-clad laminate is made. After development, check the circuit.

10. Pattern plating

After preliminary copper plating, pattern electroplating is performed, and the current time and copper plating wire are used according to the design requirements to achieve a certain plating area.

11. Alkaline etching

12. Solder mask printing

This step has the same effect as the soft board protective film. We see that PCB hard boards are generally green. This step is also called printing green oil. Check it after printing.

13. Open the lid.

Gong opening is also called opening the cover. It is the area where the soft board is located, but the area where the hard board is not needed is laser cut to expose the soft board.

14. Curing is also a baking process

15. Surface treatment

At this time, the soft-hard board (FPCB) has been prepared, and only metallization on the surface of the circuit board can prevent wear and oxidation. The general process is to immerse the circuit board in a chemical solution, but the metal elements in the solution are densely distributed on the circuit board lines

16. Print characters

Print the location of the parts to be assembled and some basic product information on the soft and hard board in the form of text

17. Testing

This is an inspection process to determine whether the circuit board is qualified. Test items are tested according to customer requirements. Generally speaking, testing includes impedance testing, open circuit and short circuit testing, etc.