our service

PCB Manufacturing

Shenzhen Wanchuang Xingda Electronics Co., Ltd. provides printed circuit board manufacturing services, providing printed circuit boards with consistent high quality and reasonable prices. Whether it is samples or medium and small batch production, we can meet your PCB manufacturing needs in various materials and technologies. We specialize in multi-layer printed circuit boards, impedance controlled circuit boards and HDI boards of varying complexity, and we offer a variety of free high-quality solutions to ensure our customers always get the best products

PCB sample

Multilayer PCB

HD PCB

High frequency PCB

Special PCB

Flying probe test

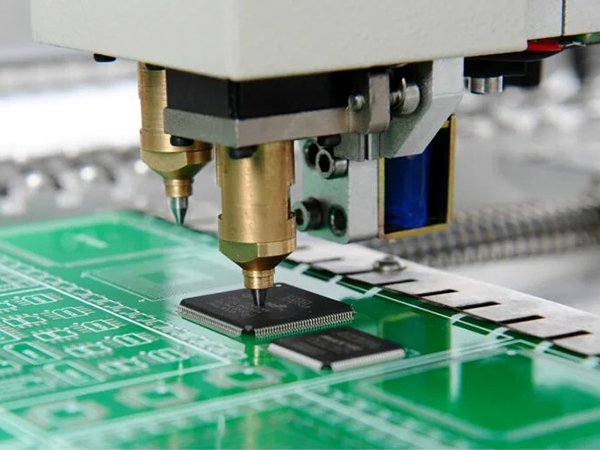

SMT patch

PCBA production size: maximum 490 x 810MM

Plate thickness range: 0.3-6.5MM

Order quantity: 1-100000pcs

Electronic components: ① Passive components, minimum package 01005; ② The minimum pin spacing can be 0.25mm

Welding type: direct plug-in components (DIP devices) / surface mount components (SMT devices) / patch and plug-in hybrid / double-sided component welding (including patches and plug-ins)

Application areas: artificial intelligence hardware, communication equipment, automotive electronics, industrial control, security, medical care, Internet of Things, etc.

SMT patch

Sample processing

DIP plug-in

BGA welding

PCBA template

Electronic component procurement

We have close cooperation with regular brand original manufacturers and thousands of first-class manufacturers. We also have long-term and stable cooperation with major electronic component spot dealers Arrow Electronics, Avnet, DigiKey, Farnell Company, Future Electronics, Mouser Electronics, Newark, and Samtec. Supplier access certification, annual audits, strict IQC inspection of incoming materials, warehouse management with constant temperature and humidity and anti-static control measures, and strict compliance with the “first in, first out” inventory control mechanism to ensure that we provide customers with first-class full BOM Parts selection service. Ensure that you receive the best service in the BOM parts selection process, from R&D and sampling to batch conversion.

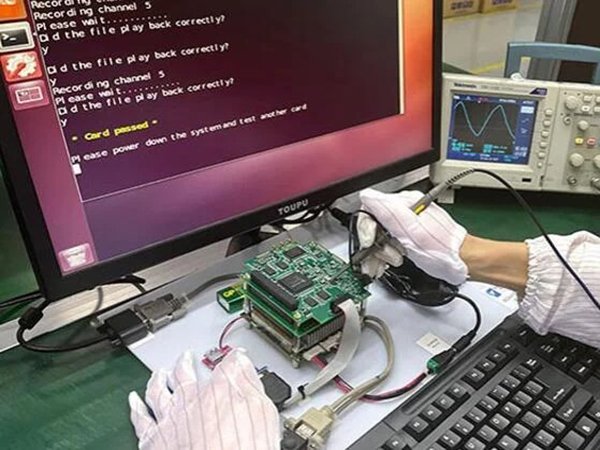

Function Test

PCBA functional testing refers to simulating the operation of the circuit board under actual use conditions to conduct electrical continuity and input and output values on the PCBA circuit board with electronic components mounted to ensure that the circuit board can work normally according to the default scheme. A kind of test. Through functional testing of PCBA, manufacturing and quality problems can be avoided and unnecessary repair costs can be reduced. At the same time, it can also ensure that the products delivered to customers are intact and improve customer satisfaction. In addition, PCBA functional testing is an important means to optimize PCB design. Potential problems and defects can be discovered and eliminated during the testing process. This helps improve and optimize the design of the circuit board, increasing the reliability and stability of the circuit board, thereby reducing the risk of crashes and failures to a large extent.

IC integrated circuit programming

We provide IC integrated circuit chip programming services. This service can be completed before the chip is soldered to the circuit board. The chip packaging covers the most conventional forms currently, including DIP, SDIP, SOP, MSOP, QSOP, SSOP, TSOP, TSSOP, PLCC, QFP, QFN, MLP, MLF, BGA, CSP, SOT and DFN, etc.

DFM/DFA inspection

Pre-production & post-production DFM & DFA manufacturability inspections can be provided in one-stop electronic assembly services. The purpose is to conduct a comprehensive inspection of the design documents before production to find various problems or potential problems that will occur in PCB manufacturing and PCB assembly to improve the customer’s design, thereby avoiding PCB/material/soldering costs caused by design errors. Improve product manufacturability and assembly; make suggestions for changes to design and defects in the production process after production, thereby avoiding batch losses in subsequent production and assisting customers in completing the transition from prototypes to batch products.

Choose Us

Turnkey

Board making – order procurement – welding – functional testing – three-proof coating – collaborative services to fully meet the different needs of customers and provide more efficient, faster and more complete value-added services for research and development

Quick-turn Prototyping

Support from 1 to 300 pcs quantities,enable you to go from design to function prototype faster and with confidence.

supply chain

Thousands of procurement supply chains can quickly purchase materials in short supply and provide services such as electronic product BOM cost accounting, risk management and control, alternative material recommendations, and complete BOM component supply.

One-on-One Service

Through dedicated service personnel, we can help you customize your needs one-on-one, respond online 24 hours a day, follow up at any time, and provide feedback on your project progress.

PCB Assembly

multilayer PCB circuit board

Professional production of 1-32 layer multi-layer PCB circuit boards (customized)

HDI PCB circuit board

Produce multi-layer 1-3 level (any level) HDI circuit board

Rigid-flex PCB

Professional production of FPC/Rigid-flex PCB 1-30 layers process can be customized

Special PCB

Can produce high multi-layer-high frequency/thick copper/metal substrate/PCB circuit boards with special materials and processes

After our service team and design team confirm the final design with the customer, the circuit board is completed through prototype design, and PCB production can be seamlessly scaled up. Our own factory meets your mass production needs, with manufacturing turnaround times as short as 24 hours and turnaround times as short as 1-2 days, we prioritize efficiency and quality, ensuring over 98% of orders are shipped on time, maintaining the highest quality and conformance standards. Overseas friends are welcome to visit the factory.

(1) We implement high-standard confidentiality measures, and all documents must be approved when leaving the country to ensure that 100% of the documents are not leaked.

(2) PCB design team has complete design software, (CadenceAllegro\ORCAD, Mentor WG\PADS

wait. ) The maximum design scale is 90000pin, which can provide HDI/Any layer PCB design, 3D PCB design, RF design, 56G high-speed design, etc.

(3) Our complete OEM foundry service provides 24-hour quotation service for your PCB assembly orders, with global Cooperate with well-known component suppliers to ensure that the electronic components are original and authentic.

(4) Owned PCB factory, monthly output can reach 60,000 square meters, no minimum PCB order requirement. It has 7 fully automatic SMT high-speed patch production lines, equipped with ten temperature zone nitrogen reflow furnace, online AOI, SPI, X-RAY and other equipment.

(5)Online quotation

Set prices based on customer documents and process requirements, 24-hour online service, and dedicated customer service to solve all your production needs

PCB Fabrication Facilities

Wanchuang Xingda Electronic Technology Co., Ltd. is a high-tech enterprise specializing in the research, development, production and sales of high-precision multi-layer printed circuit boards. The company strictly implements ISO international quality certification system and ERP system operation, lean production management, and has advanced intelligent production lines to provide domestic and foreign customers with high-quality multi-layer, high-frequency high-speed boards, HDI and other electronic circuit products. It is widely used in 5G network communications, industrial control, new energy vehicles, high-end intelligent terminals, optoelectronics, medical equipment and other fields. Committed to providing customers with high-quality products and personalized value-added services, with the goal of manufacturing world-class electronic products, and providing customers with modernization of high-quality personalized servicesLarge green environmental protection enterprise

One-Stop Turnkey PCB Assembly Facilities

Our intelligent assembly facilities consist of 8 SMT production lines, equipped with brand-new imported placement machines, ten-temperature zone reflow ovens, fully automatic solder paste printing machines, wave soldering and other high-end equipment, and are equipped with AOI, X-RAY, SPI, intelligent solder Paste detector, fully automatic deboarding machine, BGA rework station and other equipment. At the same time, we have built an intelligent BOM system that integrates more than 10 million SKUs, 45 million product data, and spot inventory data from more than 3,000 original brand manufacturers and authorized agents. You will also get a seamless experience from our 30+ professional purchasing team with over 5 years of experience and 70+ sales engineers.

Who trusts us

ABOUT US

wanchuangxingda PCB Assembly Manufacturer

Since its establishment, Shenzhen Wanchuang Xingda PCB&PCBA Technology Co., Ltd. has been providing one-stop PCB assembly services and electronic manufacturing services (EMS) to global customers in Bao’an District, Shenzhen, China. As an ISO 9001, UL, CSA and CCC certified manufacturer, we provide flexible, cost-effective and high-quality EMS solutions for Printed Circuit Board Assembly (PCBA) and complete product assembly through advanced manufacturing technology and facilities. We are a leading PCB assembly manufacturer and printed circuit board supplier in China. The special and high-level requirements of automobile regulations also contributed to the formation of the company’s quality DNA. Over the years, we have been adhering to the business philosophy of quality as the root and service as the soul, providing high-quality EMS to customers around the world.

Featured Products

Limited Time Offer

Special Edition

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Buy This T-shirt At 20% Discount, Use Code OFF20

Worldwide Shipping

It elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Best Quality

It elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Best Offers

It elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Secure Payments

It elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.