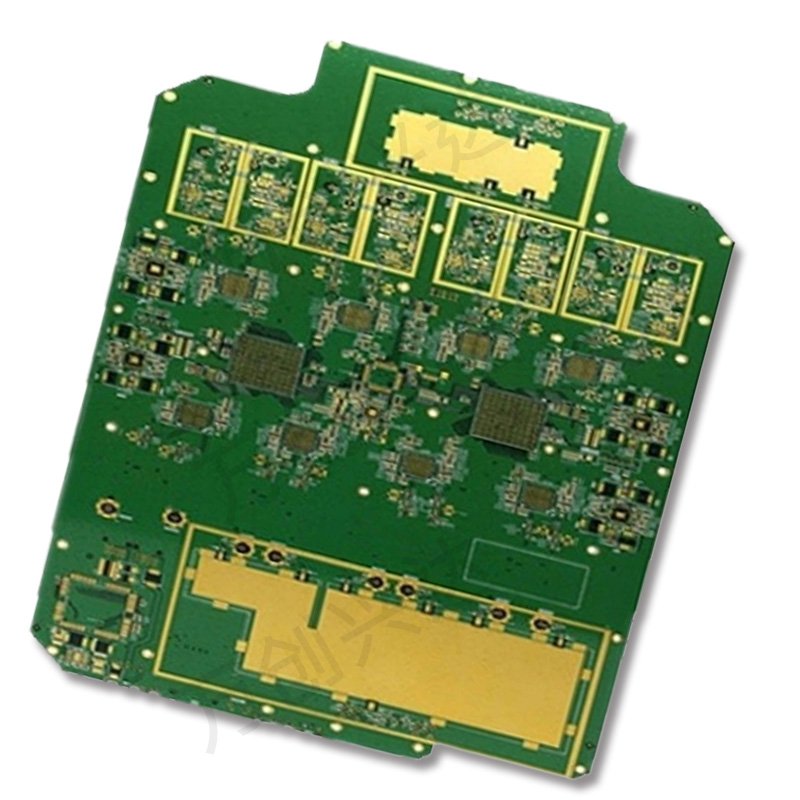

14-layer FR-4 immersion gold PCB circuit board

Material: rogers Layer Count: 14 layers

PCB Thickness: 1.6mm Min. Trace / Space Outer: 0.1mm/0.1mm

Min. Drilled Hole: 0.2mm Via Process: Tenting Vias

Surface Finish: Immersed gold +through hole

Introduction to multilayer circuit boards

in electronics manufacturing,PCB (Printed Circuit Board)Is one of the indispensable components. It serves as a support for circuit components and devices in electronic equipment and realizes circuit connections. With the continuous advancement of electronic technology, simple single-sided or double-sided boards can no longer meet the needs of complex circuit design. Therefore, multi-layer boards have emerged.

1,What is a multilayer PCB circuit board?

PCB multilayer board is a printed board made of multiple layers of conductive pattern layers and insulating materials that are alternately bonded and pressed. They form via holes through drilling and electroplating to connect the conductive patterns of each layer to achieve complex circuit interconnections. Compared with single-sided or double-sided boards, multi-layer boards can provide higher circuit density and smaller size, while effectively reducing signal interference and improving circuit performance

| Items | Manufacturing Capabilities |

| Layer Count | 1-32 Layers |

| Certifications | IATF16949 & ISO14001 & ISO9001 & UL & RoHS & CQC & REACH |

| Materials | Fr-4, Aluminum, Rogers, Arlon, Polyamide. |

| Board Thickness | 0.6-2.5mm(Special thickness can be made, but it needs to be judged according to the documents) |

| Min. Trace Spacing | 3.5mil |

| Min. hole size | 0.2mm |

| Solder Mask | green, red, white, yellow, blue, black, and matte black solder mask color. |

| Surface Finish | HASL/Lead-free HASL /ENIG/OSP |

2 What is the structure of multi-layer boards?

(1)Conductive layer: also called copper foil layer, it is the layer used to arrange wires and solder components on the circuit board.

(2)Insulating layer: usually composed of epoxy resin, fiberglass and other materials, used to isolate different conductive layers.

(3)Via hole: A hole connecting different conductive layers, usually made by drilling and plating processes.

(4)Solder mask: A thin film covering the conductive layer to prevent oxidation of the copper layer and limit the flow range of solder during soldering.

(5)Surface coating: such as gold, silver or tin, etc., used to protect the surface of the circuit board and provide a good electrical connection.

3 What are the advantages of multilayer boards?

(1)High density: Multilayer boards can arrange more circuits and components in a limited space, suitable for the design needs of complex circuits.

(2)High performance: Multilayer boards offer better electrical performance and signal integrity thanks to the availability of blind, buried, and microvia technologies.

(3)Miniaturization: As the number of layers increases, the size of the circuit board can be further reduced, helping to achieve thinner, lighter and smaller electronic products.

(4)High reliability: The multi-layer board design is more compact, reducing possible interference and the risk of physical damage, and improving overall stability.

4 Application scenarios of multi-layer boards

Multilayer PCB boards are widely used in various high-performance electronic devices, such as smartphones, tablets, advanced graphics cards, satellite systems, medical equipment, military equipment, etc. These applications place extremely high demands on circuit performance, size, and reliability.